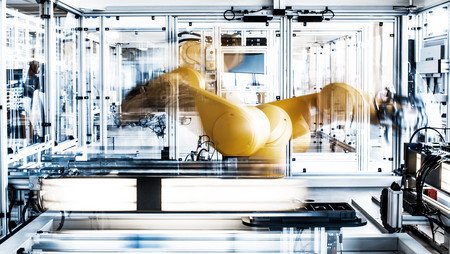

Intelligent automation is the future of intralogistics. Increase your capacities with our gantry robot solutions. Safe and reliable.

Gantry technology is a versatile and adaptable principle in intralogistics: the pick-up and drop-off locations on the line, a surface and in space can be programmed easily and reliably using Cartesian coordinates, and the grippers can be positioned with high precision using stable travel axes. The drives are low-maintenance. The load pick-up can be designed for light or heavy loads without changing the basic concept.

Stöcklin uses gantry robotics in complete system solutions, particularly for stacking transport containers - both on rack-free large areas and for compact palletizing. Our experts always focus on the development and adaptation of gripper technology for special applications. We have a great deal of expertise and impressive references in this area.

You can increase the efficiency of your palletizing processes with our solutions. Our robots stack transport bundles and cartons on pallets or remove them with a precision and speed that cannot be achieved manually. This not only ensures optimum utilization of the available space, but also a significant reduction in cycle times.

Intelligent: With intelligent control from our logOS software suite, you can achieve adaptable automation of repetitive tasks, minimize the risk of damage and errors. And sustainably increase your productivity.

Adaptability: Our robot solutions are fully customizable and can be tailored to your specific requirements.

Improved working environment: With our robotic solutions, you reduce the physical strain on your employees by shifting heavy lifting tasks, thereby improving occupational safety.

Long-term cost savings: Our robotic solutions offer a quick return on your investment through reduced labor costs and increased production capacity.

Depalletizing and repalletizing for deliveries to the stores - directly from the producer - onto the store mix pallet.

CasePicker Solution

With pick & place robot solutions from Stöcklin, your packs are safe on the move.

Pick & place robots